Logistics have become a critical component of a zero-waste lifestyle. Logistics support the back-end systems for all the front-facing zero-waste initiatives of a business. All logistics are not equal; logistics vary depending upon the products that are being sold, the storage space needed for these products, and the collection and delivery schedule for products and supplies. Every product has its own unique movement pattern, and each product’s pattern requires careful management to ensure that no waste occurs.

When logistics are functioning properly, staff waste less time and use less energy, and they are confident in their ability to meet the sustainability objectives of their employer.

Refill Shops are Not Easy to Operate

Many customers assume that operating a zero-waste store involves simply filling bulk containers from large containers that are delivered to the store without incident. While it is true that bulk containers do not typically contain single-use packaging, the reality is that there are numerous logistical issues that arise when using bulk containers. For example, if perishable products such as coffee beans are shipped in bulk containers, they must be stored in a way that prevents moisture and light from affecting the quality of the product, which creates additional storage requirements. Additionally, suppliers often ship goods in heavy reusable drums that stores must return. Those returns require staging areas and clear transport plans. These logistical considerations create operational complexity that is often overlooked. Zero waste shops succeed because they treat these details as core to their identity.

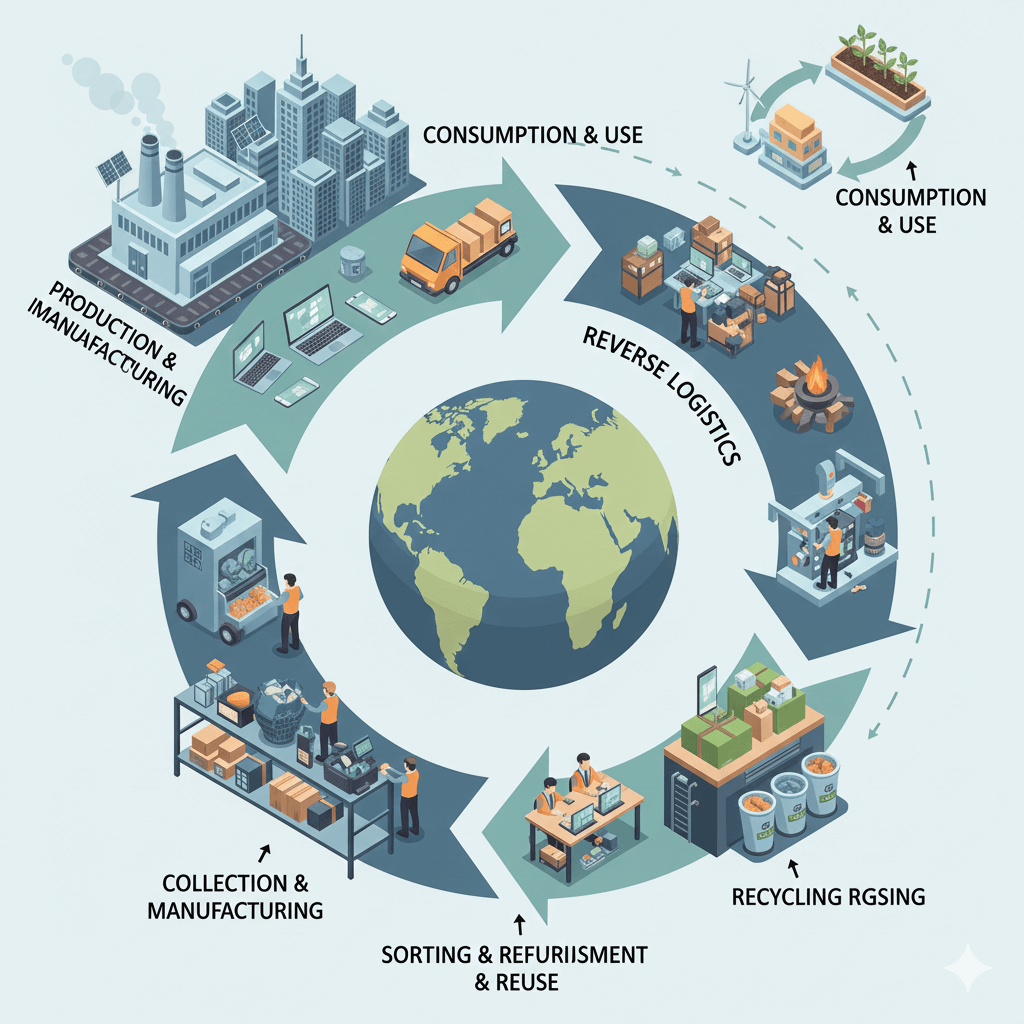

Reverse Logistics Must Be Managed Daily

Conventional retailers focus on receiving goods. Zero-waste retailers operate in two directions. They receive bulk shipments, and they return reusable containers, pallets, crates, or drums to suppliers. This process is known as reverse logistics, and it demands precision from everyone involved. If empties are not cleaned correctly or stored well, a supplier may reject them. That can delay production or interrupt inventory. Businesses that excel in reverse logistics treat it as an ordinary routine rather than a chore.

Haulers Help Build a Circular Economy

A circular economy operates efficiently through local movement. A smaller distance means fewer emissions and lower cost. The haulers, recycling centers, and compost services in a region are key players in this system. They remove non-reusable materials like food, deal with contaminants that cannot be sold to other companies, and send the non-reusable materials to facilities that will recycle or compost the materials. Businesses find that working with reliable haulers provides a significant boost to their zero-waste efforts over developing new displays or marketing campaigns. In addition, many of these haulers assist companies in understanding and complying with local government rules regarding sorting and handling materials such as organic waste, cardboard and glass.

Not All Waste Can Be Eliminated

No matter how committed a zero-waste business is to eliminating waste, some amount of waste will always exist. It may include a broken jar, spoiled food, or a damaged bulk container. What matters is not whether waste exists but how it is managed. A business should monitor the source of each category of waste, identify trends, and set goals to reduce waste. Some businesses analyze contamination events, while others evaluate how employees handle particular materials. Through the use of data-driven approaches, businesses can significantly reduce waste levels without placing undue burden on their operations.

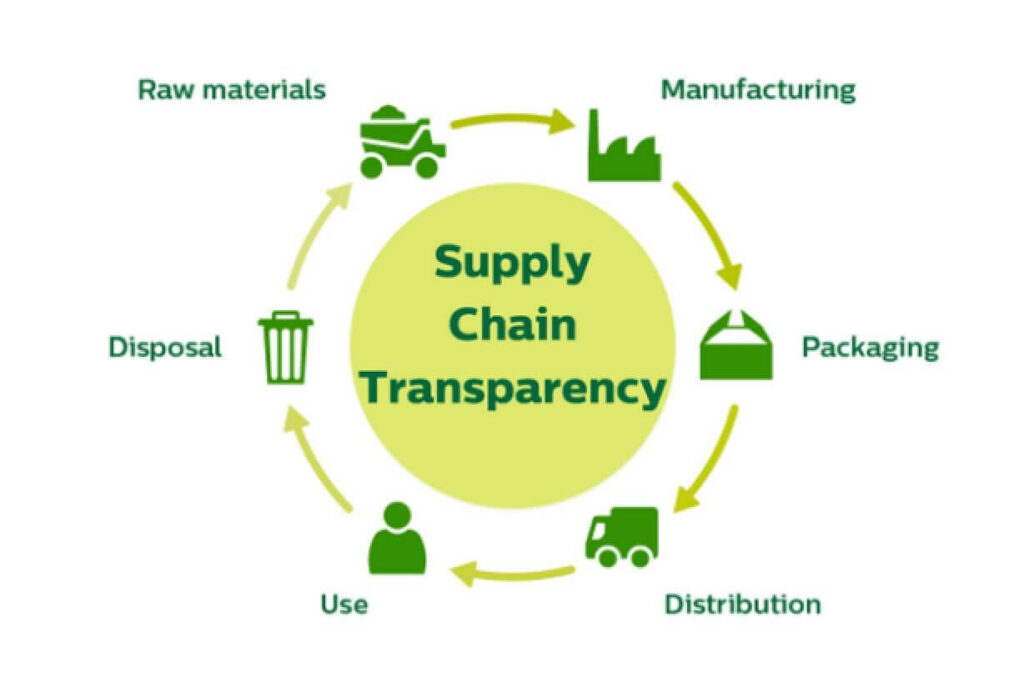

Leadership and Supply Chain Transparency

Business leaders frequently discuss the importance of transparency; however, the implementation of a zero-waste policy necessitates a far more tangible application of the concept. To operate a zero-waste store, a business must know the origins of every product and every container it uses. A business must verify the cleaning processes used by suppliers of reusable drums. A business must understand how local haulers handle specific materials. Labels with adhesives, coatings on bags, or resin codes on containers can affect whether an item is recyclable. When businesses develop long-term relationships with partners throughout the supply chain, they make decisions that align with their stated commitment to sustainability.

Operational Clarity Builds Customer Trust

Customers like the ideals of zero waste, but they generally have little insight into the amount of coordination required to run the shops they favor. Businesses can establish trust with customers without providing too many details by explaining how they manage their operations. Some stores give behind-the-scenes tours of their facilities. Other stores post photos and videos illustrating how they return packaging or manage compost. Some stores document their experiments with new systems based on customer feedback. This type of communication fosters a connection between customers and the mission of the business and increases the likelihood that customers will return.

How Recycling Infrastructure Is Evolving

Zero-waste models becoming more prevalent have changed how some companies view waste after it leaves their buildings. New technologies in waste recycling have made it easier for waste haulers and facilities to sort, identify, and recover materials that were previously sent directly to landfills. Improved material recovery systems, optical scanners, and cleaner processing lines allow businesses to be confident that what they do by separating recyclable materials from non-recyclable materials will result in true recycling. This advancement helps to remove uncertainty for zero-waste operation and validates why a business should partner with organizations investing in modern systems, versus viewing waste as one large, unsorted flow.

Tools and Technologies That Help Reduce Waste

With digital tools, businesses are able to monitor their bulk inventory levels, scheduled returns for containers, cleaning of dumpster containers, and time in advance of pickups, therefore allowing their teams to identify friction points prior to them turning into waste. Additionally, some businesses utilize forecasting software that anticipates their shrink and spoilage based upon seasonal changes, which allows for a less stressful experience when placing orders as well as for more intentional use of storage space. The hauling partners that enable the movement of goods via these systems have their own need for digital tools to simplify the process of scheduling and customer acquisition. This is due to the fact that consistent demand from customers enables better routing options for haulers and subsequently increases response times for both the hauling partners and the customers. Therefore, platforms focused on dumpster rental leads can be part of the broader efficiency story.

The Next Generation of Zero-Waste Innovation

The next phase of innovation in zero-waste will not primarily involve the development of new products or packaging concepts. Rather, future innovation will come from streamlined logistics, improved collaboration among stakeholders, and innovative regional networks. Small suppliers may collaborate on joint return trips. Local haulers may expand specialized services to assist retailers with managing niche materials. Warehousing operations may use modular storage systems that keep reusable containers in pristine condition. Improved logistics in the region increase the resilience of the entire ecosystem.

While a zero-waste lifestyle appears to be relatively easy to achieve, the underlying logistics represent a complex and dynamic environment of thoughtfulness and cooperation. Every reuse, every refill and every compost collection represents a commitment to closing loops instead of increasing them. Businesses that recognize this reality discover that sustainability is not merely an attractive marketing strategy; it is a daily practice based on collaborative partnerships, efficient systems, and continuous innovation. As more businesses embrace this perspective, the benefits of a cleaner street, a more cooperative community, and the perception that progress is achievable and accessible extend beyond the business itself.